WINDNLIGHT

In WINDNLIGHT we are always searching for solutions to problems within the wind and solar industry. Most of our experience is in the wind blade manufacturing industry. We focus in process optimization, mould design and manufacturing, and blade tooling in general.

We look for simple, cost effective solutions with the highest impact on speeding up time to market and lowering production cost.

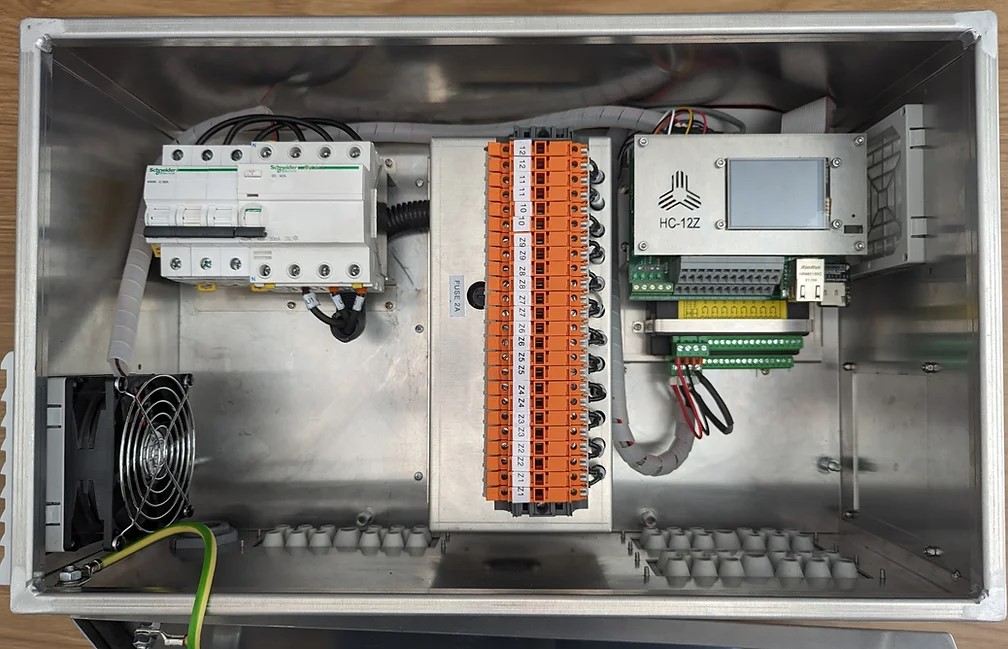

12 independently controlled heat zones, designed specifically for directly heated moulds.

Plug and play Stand-Alone heating unit including PLC and HMI, specifically designed for curing top laminate of composite wind blade shells and webs.

Web Air Cavity Heater Stand-Alone

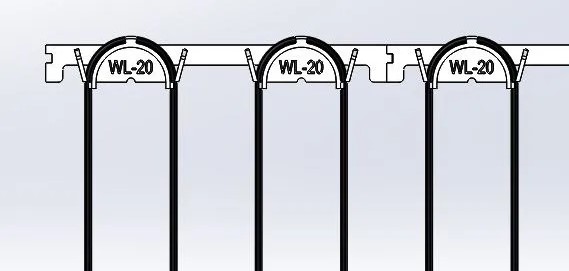

Retaining system for attaching mould upstands to a mould. Replaces bolts, magnets, etc.

Snap heating cable into place – No more gluing cable required

Different cable pitches available: